partial stress-relieving annealing

circumferential weld

It is necessary, in all partial heat-treatment operations, to take account of possible obstructed expansion and its effects on the component. Special attention must therefore be devoted to questions of expansion and contraction.

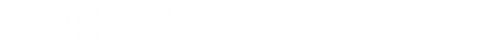

Particularly in this case, where a 446 mm thick pipe bend with a shell section and a hemispherical head of 85 mm wall thickness were located only 400 mm from the annealing sites (circumferential weld, D = 2,600 x 35 mm wall thickness). A stress analysis, which specified the axial and radial plots of temperature, was drafted in order to keep the stress exposure of the HP preheater within permissible limits during heat treatment. It was also necessary to bear in mind that the HP preheater’s supports (fixed and floating bracket) were located only 150 mm from the annealing site. The deadweight of the shell section of the HP preheater had caused it to deform during stress-relieving annealing. For this reason, 85 t of the HP preheater had to be suspended at above 300 °C using the machine shop crane. The residual load on the fixed and floating brackets was thus only 5 t. The crane’s load was continuously reset to 85 t during heat treatment, in order to compensate for the axial expansion caused by the heat.

PDF - Control and instrumentation diagram

Downloadpartial stress-relieving annealing

closure weld

Components of the most diverse geometry and sizes can be partially heat-treated on site at rational cost using a mobile furnace. Such furnaces are also suitable for use, for example, on tube-sheet welds, circumferential welds to adjacent components, series heat-treatment operations, etc.

The benefits in detail:

• Uniform heat input throughout the component cross-section

• Unrestricted distribution of heating elements

• Individual setting of zone temperatures

• Temperature control via of selection of time and heat input rate

partial stress-relieving annealing

roll shaft

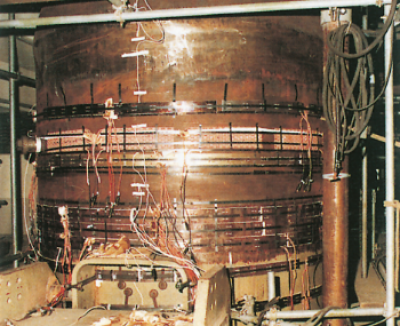

Due to the specified axial temperature-distribution diagrams, heat-treatment operations are tied to logical procedures and rules.

All details must have been carefully thought out and planned for cost-efficiency before the process starts, in order to permit adherence to the recommended codes and specifications. As in this case, where the running surface of a roll shaft with a diameter of 1700 mm and a width of 600 mm was to be heat treated. In addition, the temperature on the roll necks had to remain below 400° C, since these machined surfaces would otherwise have oxidized, causing scale. The roll necks were also pretreated with INPRO's special Zunderstop antioxidant agent.